Selecting a good cell is the key to success for any battery related application whether it is electric vehicle or stationary energy storage or any kind of portable application. We perform all kinds of required tests to help you to select the right cell technologies/manufacturers.

Why testing from us:

– Test planning and execution from very professional personnel.

– Evaluation/visualization of the test data with matlab on a regular basis.

– Saving lab infrastructure & expensive equipment cost.

– Saving cell test engineer cost.

– Necessary raw test data would be provided via google drive.

Cycle Life Test

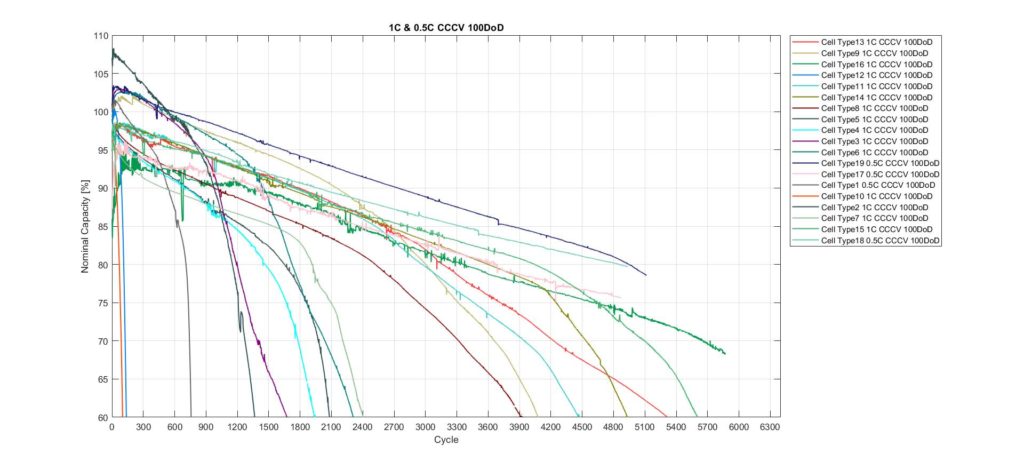

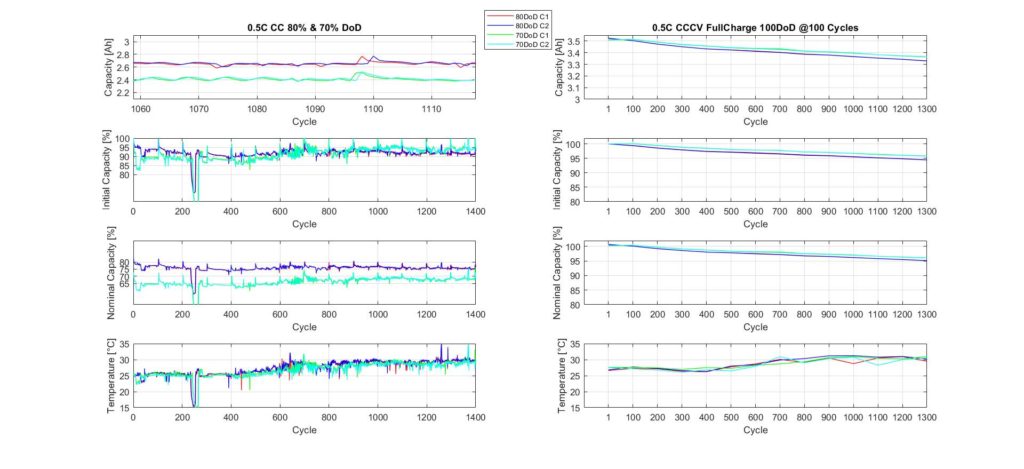

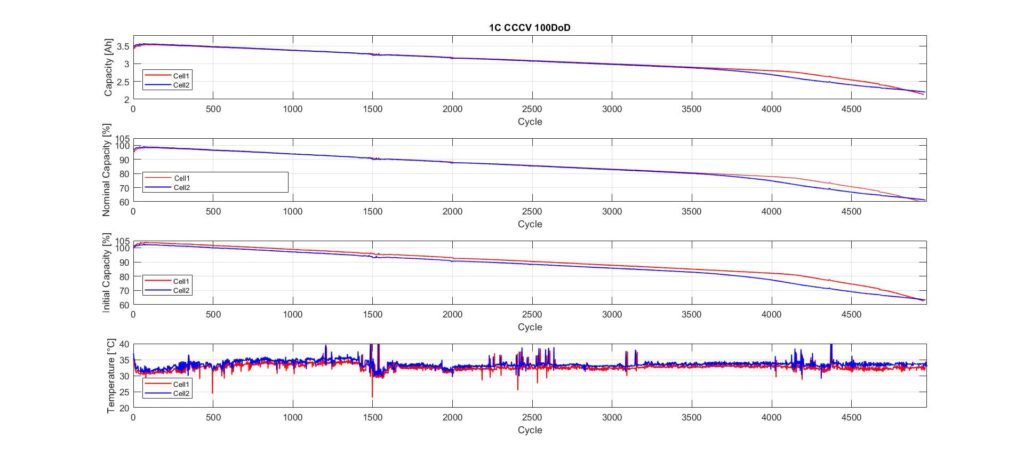

Cycle life test is the most effective way to justify the performance of a cell. Although it takes a long time but still, this is the most reliable way to qualify any cell manufacturer.

Every cell manufacturer would say that they have the best cells, even their specification would say that their cell would last for a couple of thousands cycles.

My experience says that cycle life for some manufacturers could last for just a couple of hundred cycles, so it would be wiser to justify them before going further…

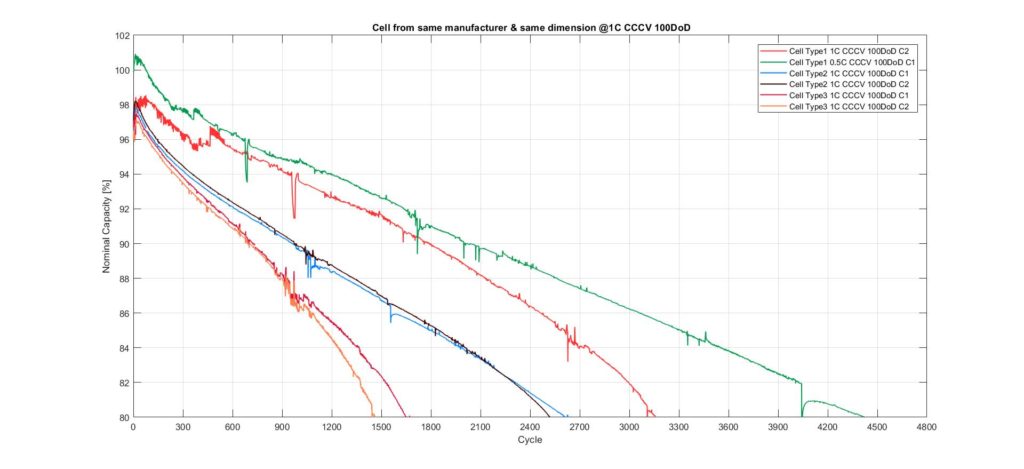

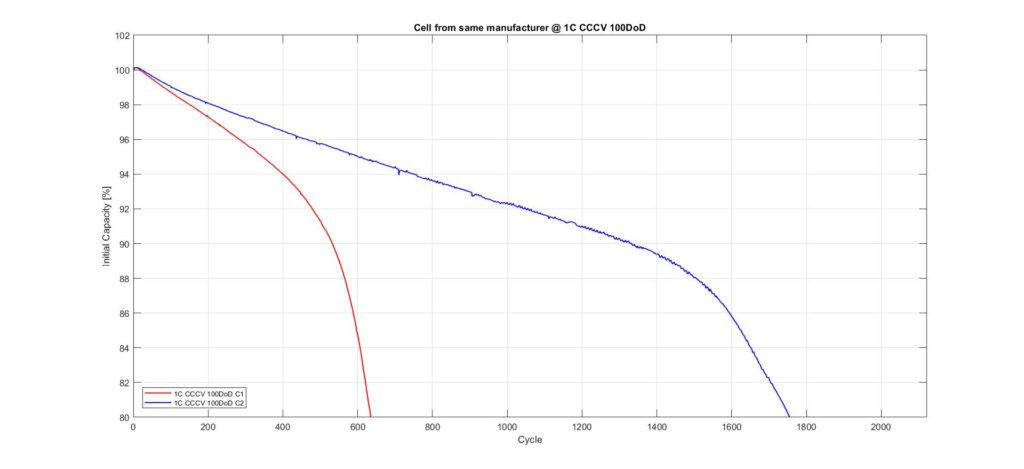

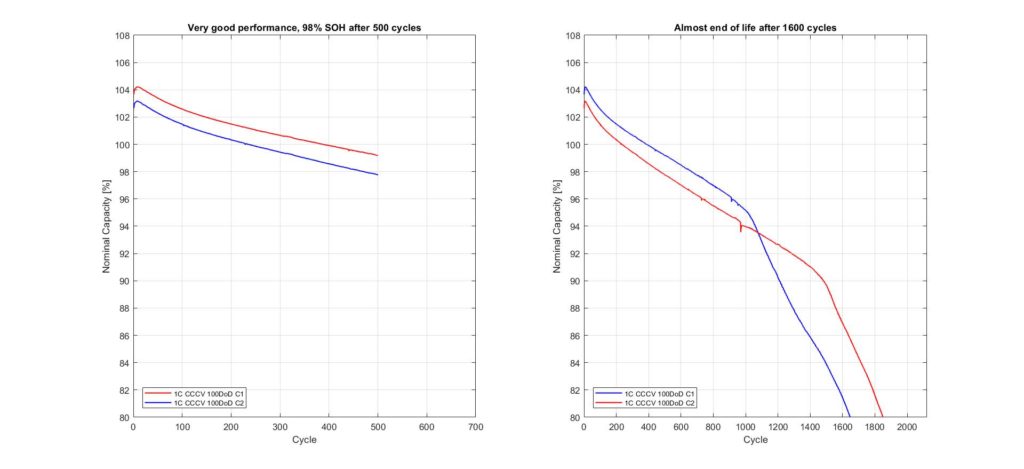

Pay attention to the performance consistency of your cell. Inconsistency in cell performance could cause poor module behavior.

It could happen that one cell is performing very well and another cell from the same production batch could suffer a lot. So test more samples to check consistency in performance…

Don’t stop testing until you get desired results. Having good performance during the first couple of hundred cycles doesn’t mean that the cell is gonna last longer.

Figure depicts that the state of health (SOH) for the initial 500 cycles was around 98% but after 1600 cycles the cell capacity reached its end of life state.

Calendar Aging Test

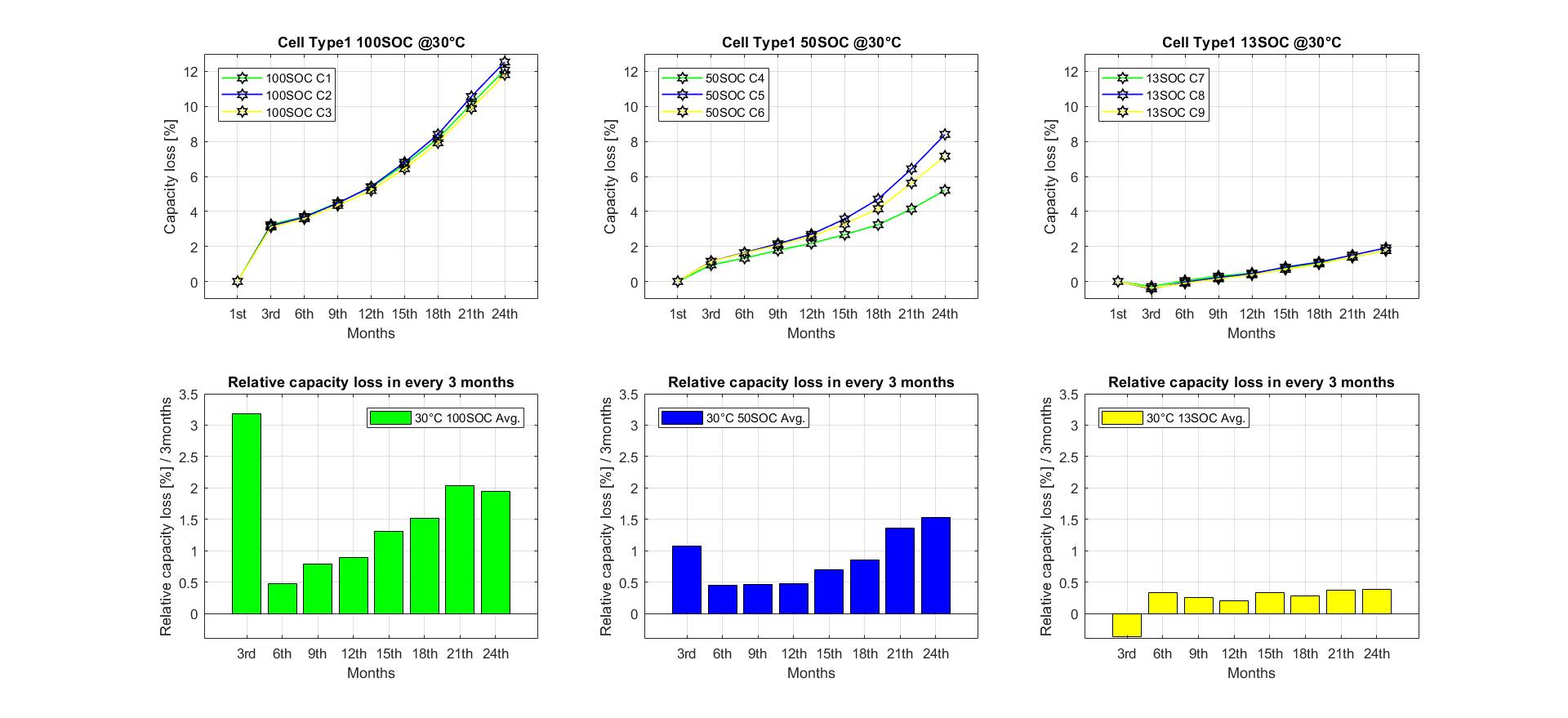

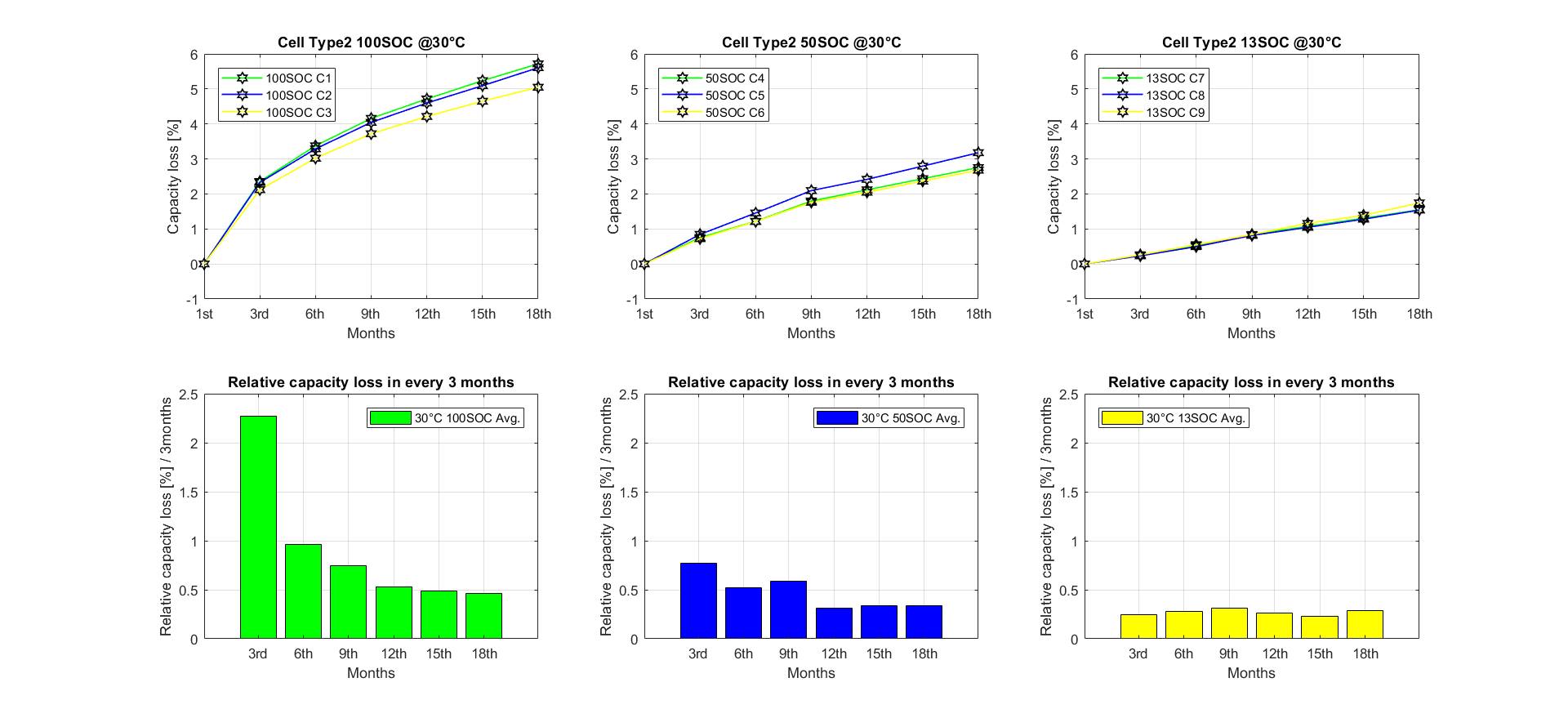

Having a good cycle life performance doesn’t guarantee a good calendar aging behavior.

Different cell manufacturers add different types of additives into their electrolyte in order to improve their cell performances (E.g.: improved low temperature behavior, low internal resistance and so on..). That’s why the aging process is different for different manufacturers.

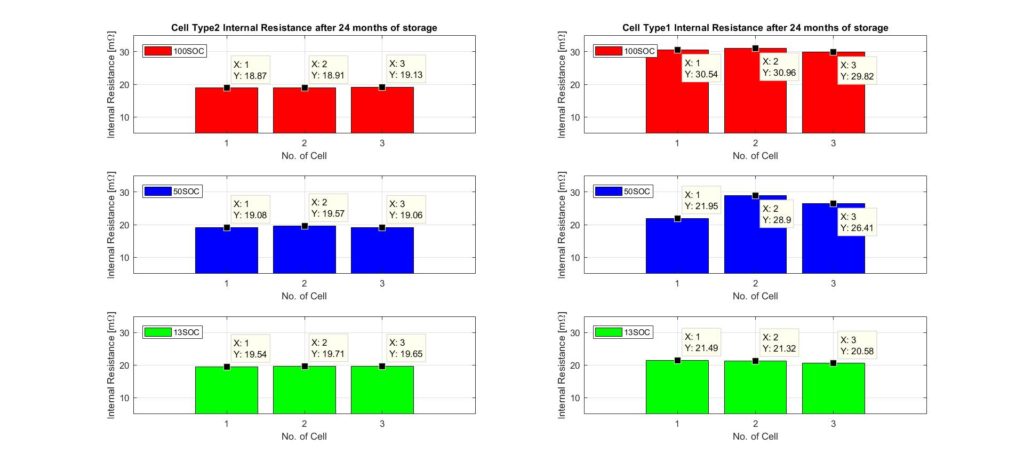

The figures depict calendar aging behaviors of two cells from two different manufacturers. It shows that the calendar aging of one manufacturer is increasing slowly while in the case of another manufacturer it is increasing very fast, although both cells had very similar cycle life characteristics.

If you intend to use lithium ion battery for several years then you must pay attention to their calendar aging mechanism along with the cycle life performance.

The internal resistance of cells changes along with aging, but this change is not same for all the manufacturers. Figure shows a huge difference in internal resistance for two different manufacturers (same cell chemistry / same cell format).

During the aging test we keep track of both capacity and internal resistance at 3 different SOC (100SOC, 50SOC & 13SOC) to understand the optimal usable range of the cell.

Capacity Test

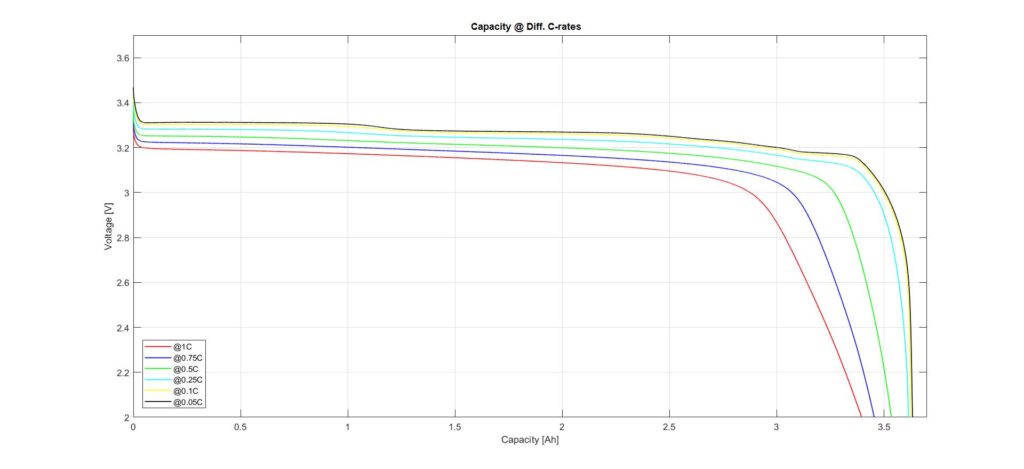

Every cell has a specific nominal capacity. Usually battery/cell price is based on KWh, and KWh is calculated from the nominal capacity of the cell.

Sometimes it could happen that the cell’s original measured capacity is lower than the specific nominal capacity. So, it is wiser to measure real capacity of the battery/cell, otherwise it might happen that you are getting less than the amount you are paying.

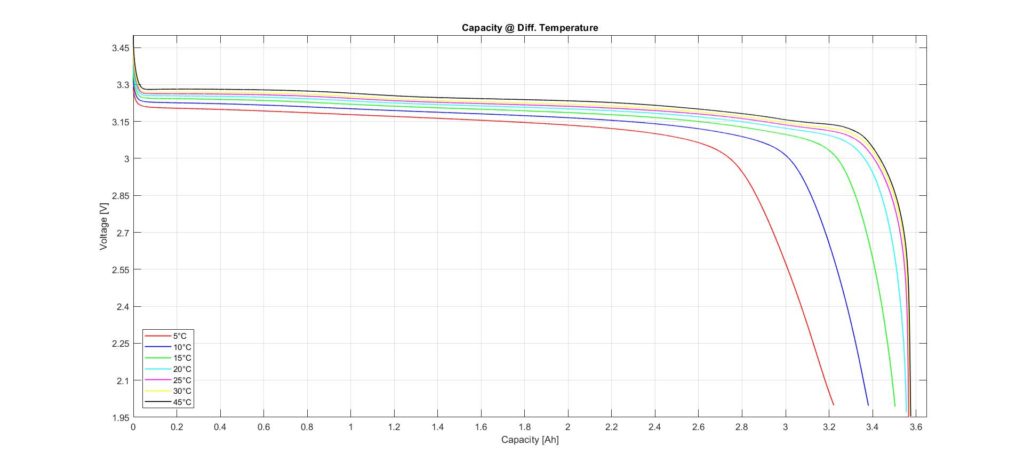

The available capacity of the battery is not the same for all the operating conditions. Usually capacity varies a lot with temperature, specially at low temperature, due to high internal resistance the usable capacity of the cell would be very low.

Thats why its very important to know your battery capability at different temperatures, so that you can ensure smooth operation of the load/appliances without violating safety limits of the cell

Cell Modeling

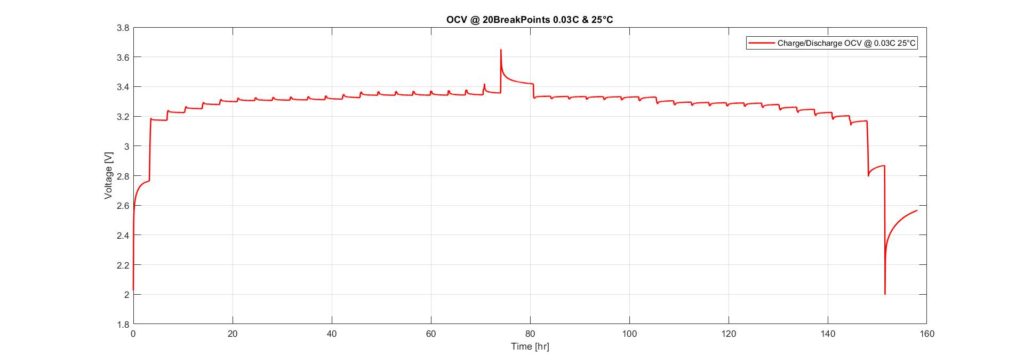

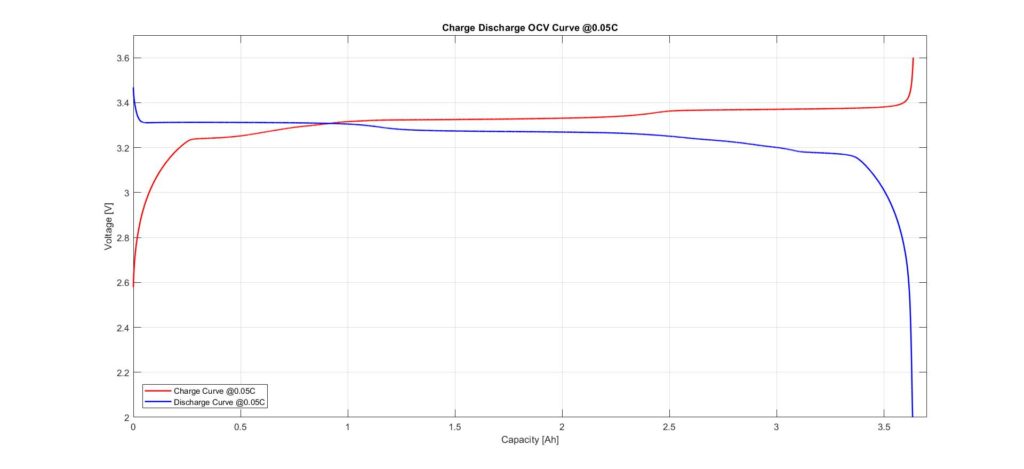

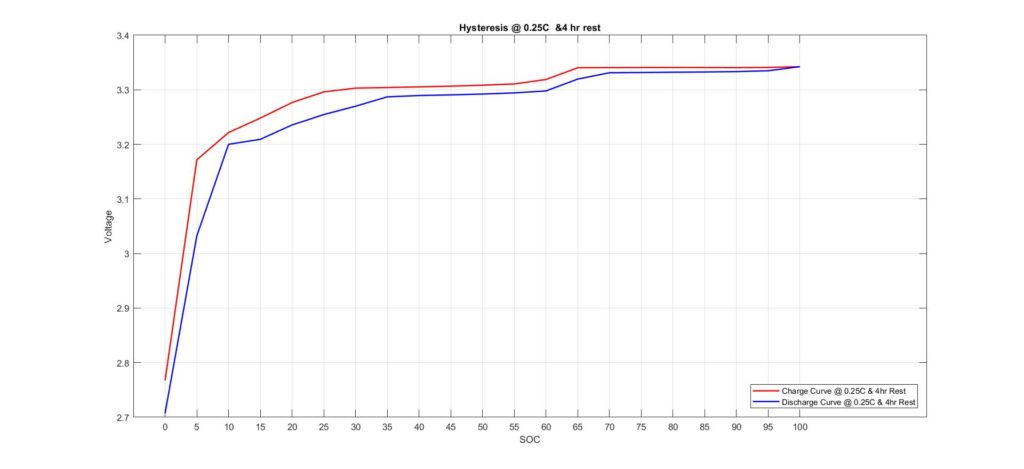

In order to have an accurate SOC estimation you need to consider a lot of aspects. Due to hysteresis, the charge and discharge curve of a lithium cell is not identical.

This way of measuring OCV curve (20 break points @every 5% SOC) would help the algorithm developer to calibrate their calculated SOC.

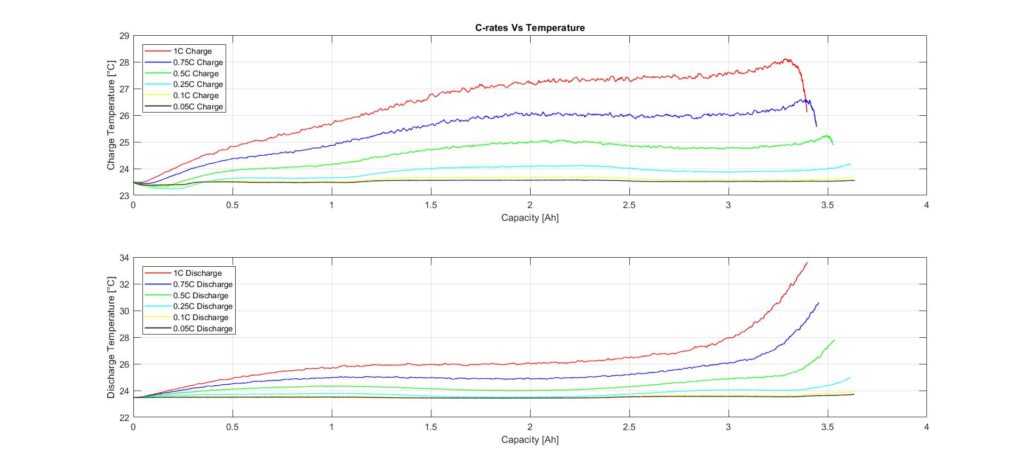

Temperature Effect

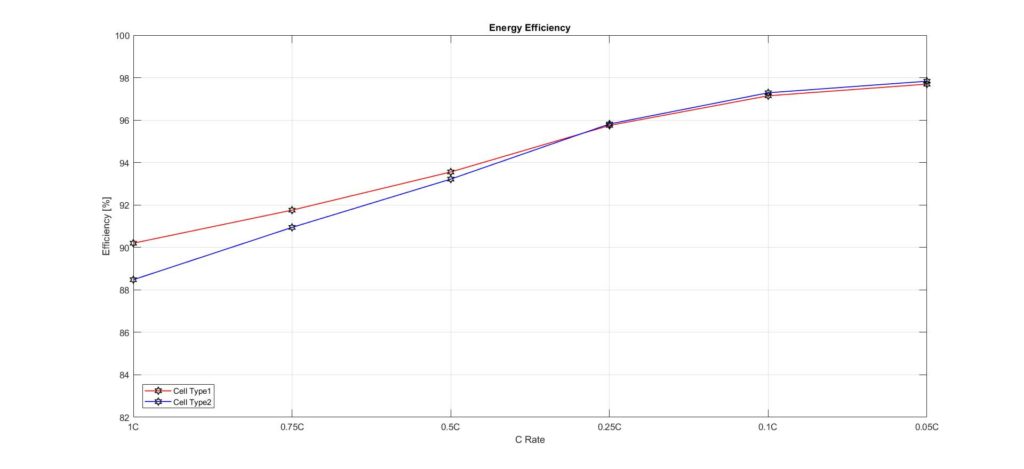

Efficiency

Internal Resistance

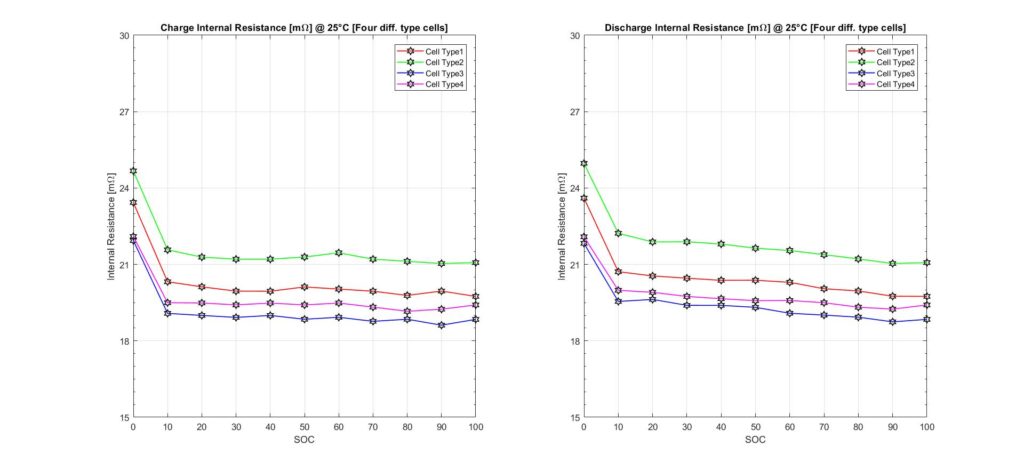

Internal resistance mainly varies depending on the cell format (cylindrical/prismatic/pouch), size and on their electrolyte additives.

Higher internal resistance reduces the power capabilities of your battery. It increases heating during the charging and discharging process. Heating causes temperature rise and high temperature is the most dangerous thing for lithium battery, it reduces battery life drastically

That’s why it’s very important to select cells with low internal resistance to prolong battery service life and reduce thermal management cost.

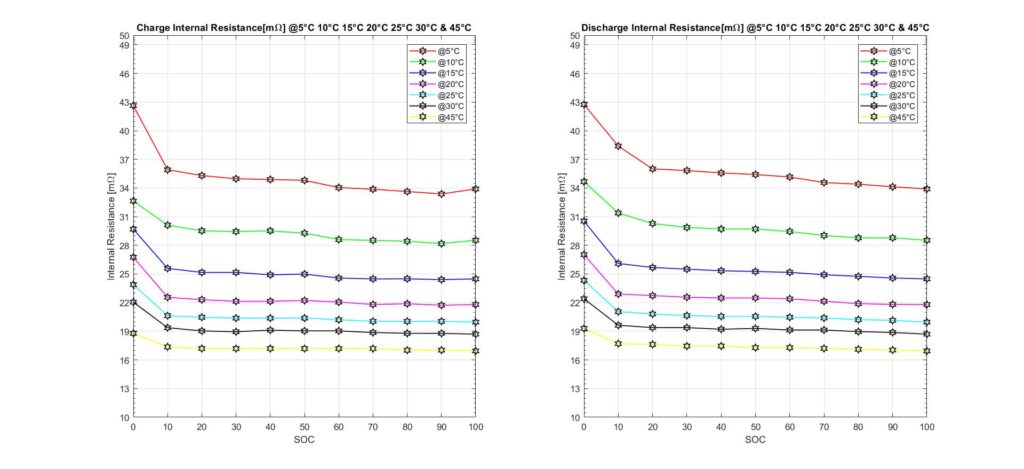

Temperature has a huge impact on internal resistance, specially at low temperature the internal resistance is very high.

At low temperature It could appear that your battery couldn’t deliver proper power to your load/appliance.

By knowing the internal resistance at different temperatures you can properly set your power limits to ensure smooth operation.

Safety / Abuse Test

Safety is the most important topic for Lithium batteries. If you don’t use them in a proper way then there might be a chance of a hazardous situation.

Abuse conditions (over charge / over discharge / internal short circuit) could increase the internal pressure of the battery. As the pressure increases, the temperature will rise, the high temperature will melt the separator, which will create a short circuit between anode and cathode and eventually could lead to a thermal-runaway condition.

Different manufacturers use different safety devices (PTC/CID/Safety Vent) to reduce the risk of thermal runaway. Make sure that your battery has safety devices and they are working properly to avoid fire related hazardous situations.

We perform abuse tests (over charge / over discharge) to make sure that the safety devices (PTC/CID/Safety Vent) of your battery’s are working properly.

PTC: Positive Temperature Coefficient

CID: Current Interruption devices