No matter how sophisticated your BMS design is, no matter how robust your module design is, selecting poor quality cells will ruin all of your effort.

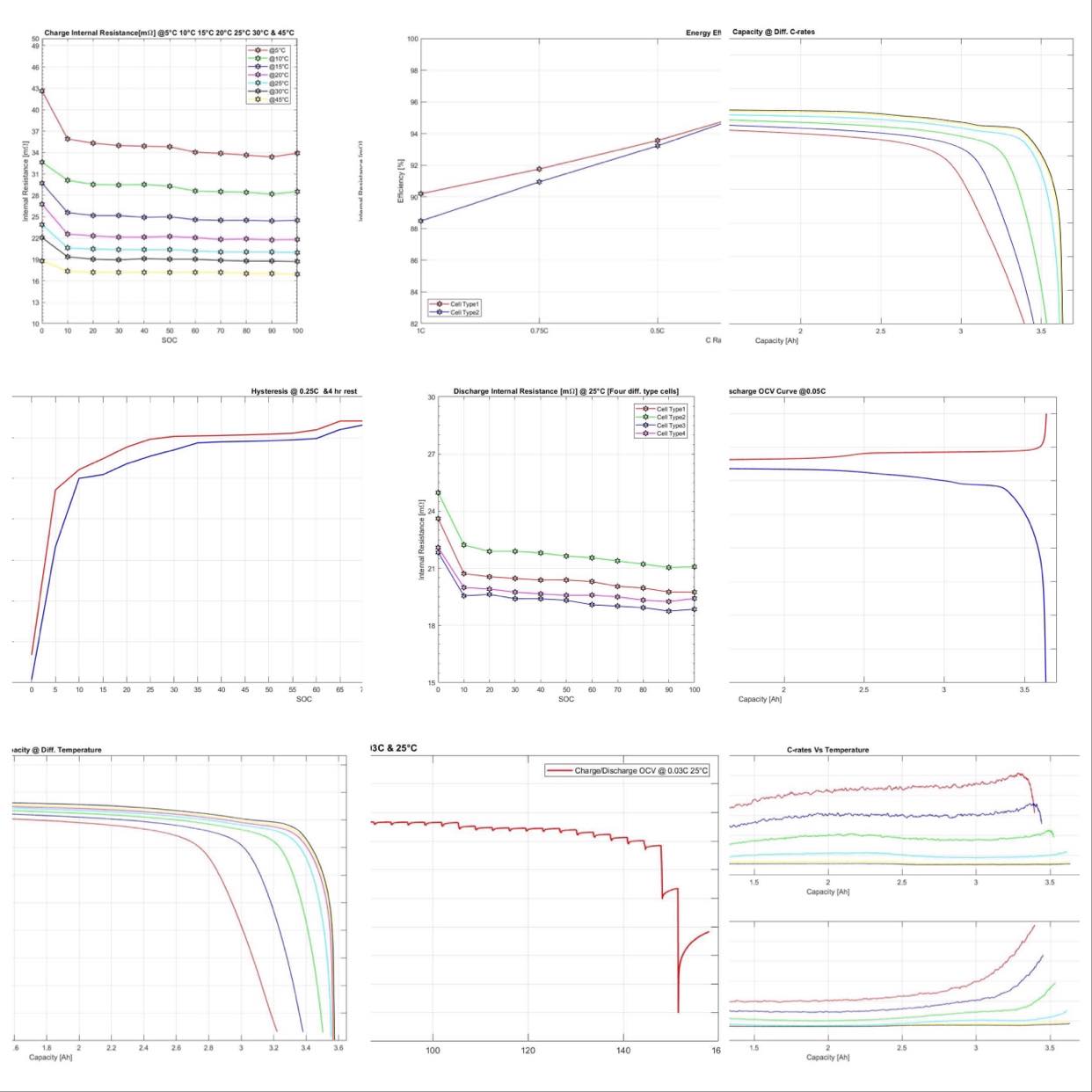

We perform: Cycle Life / Calendar Aging / Efficiency / Cell Modeling / Internal resistance / Abuse Test and so on …….

More information on ‘’Testing’’ page

Talking with expert would save time, money and prevent from going wrong direction

10 Years of Experience in Lithium Battery Research & Testing

We are ready to support you for finding the best cell technologies and manufacturers.

Testing

Cycle Life Test

How good a cell is!! How it can be determined!!

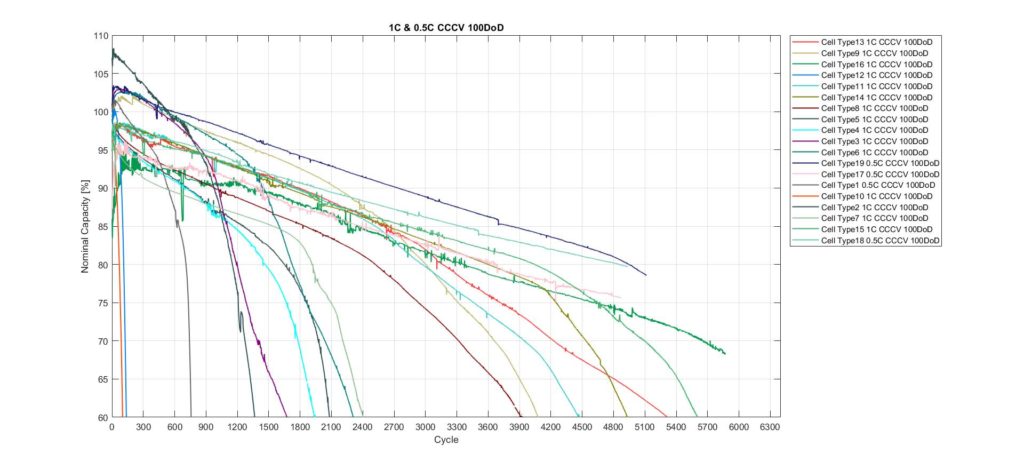

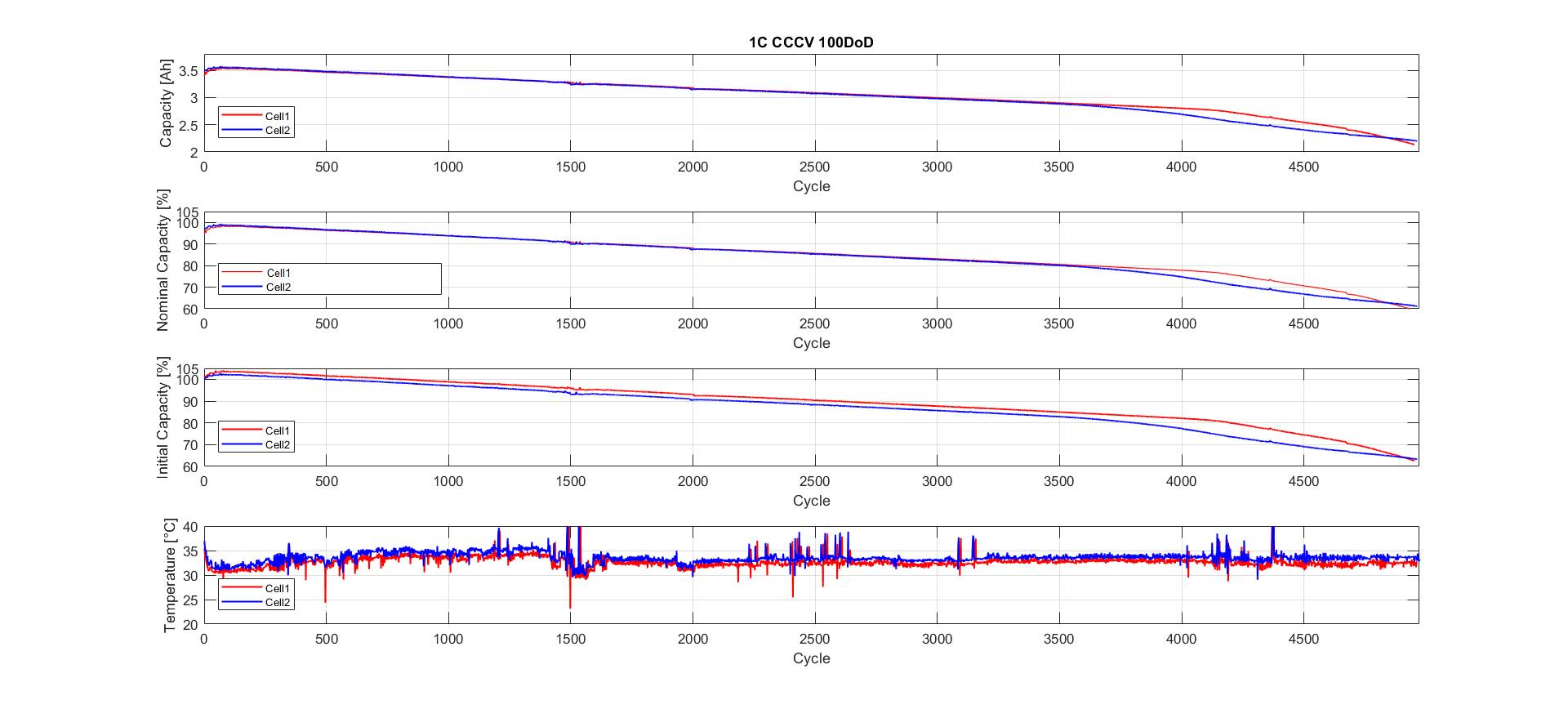

Cycle life test is the most effective way to justify the performance of a cell. Although it takes a long time but still, this is the most reliable way to qualify any cell manufacturer.

Every cell manufacturer would say that they have the best cells, even their specification would say that their cell would last for a couple of thousands cycles.

My experience says that cycle life for some manufacturers could last for just a couple of hundred cycles, so it would be wiser to justify them before going further…

Calendar Aging Test

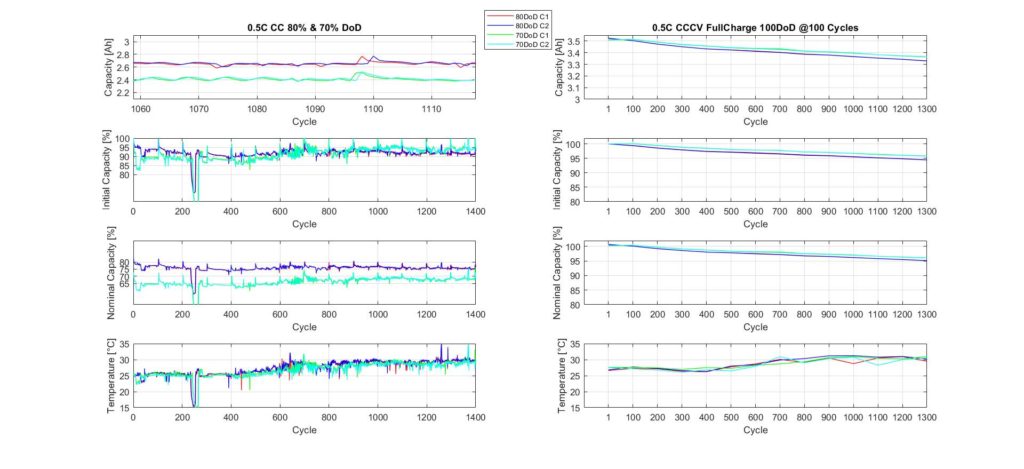

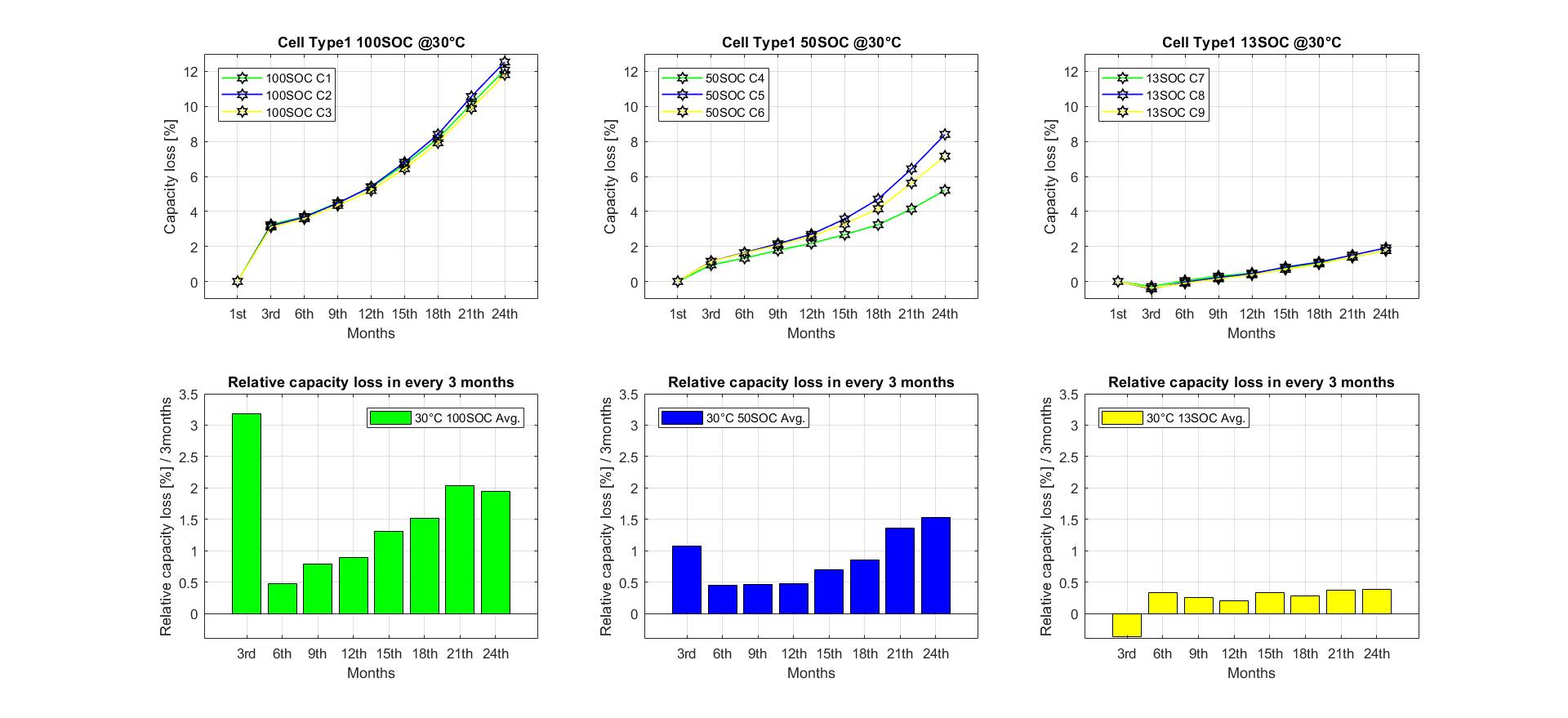

Having a good cycle life performance doesn’t guarantee a good calendar aging behavior.

Different cell manufacturers add different types of additives into their electrolyte in order to improve their cell performances (E.g.: improved low temperature behavior, low internal resistance and so on..). That’s why the aging process is different for different manufacturers.

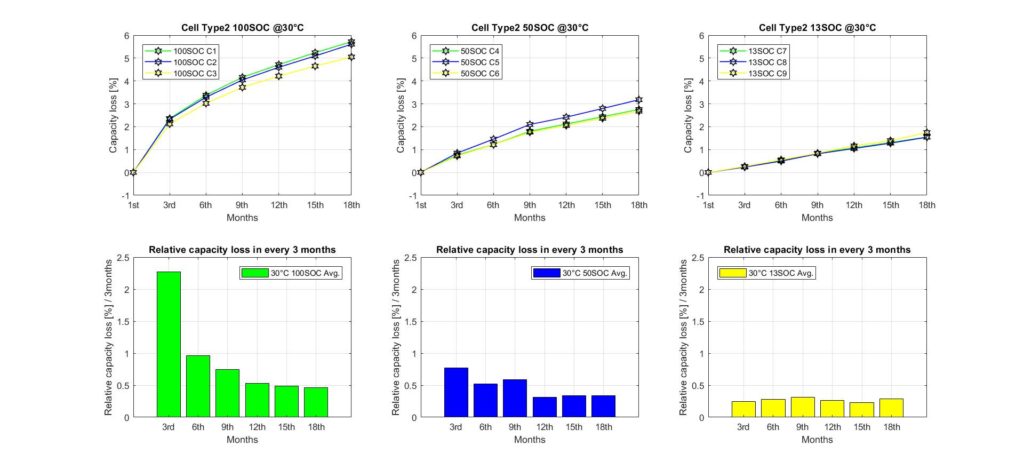

The figures depict calendar aging behaviors of two cells from two different manufacturers. It shows that the calendar aging of one manufacturer is increasing slowly while in the case of another manufacturer it is increasing very fast, although both cells had very similar cycle life characteristics.

If you intend to use lithium ion battery for several years then you must pay attention to their calendar aging mechanism along with the cycle life performance.

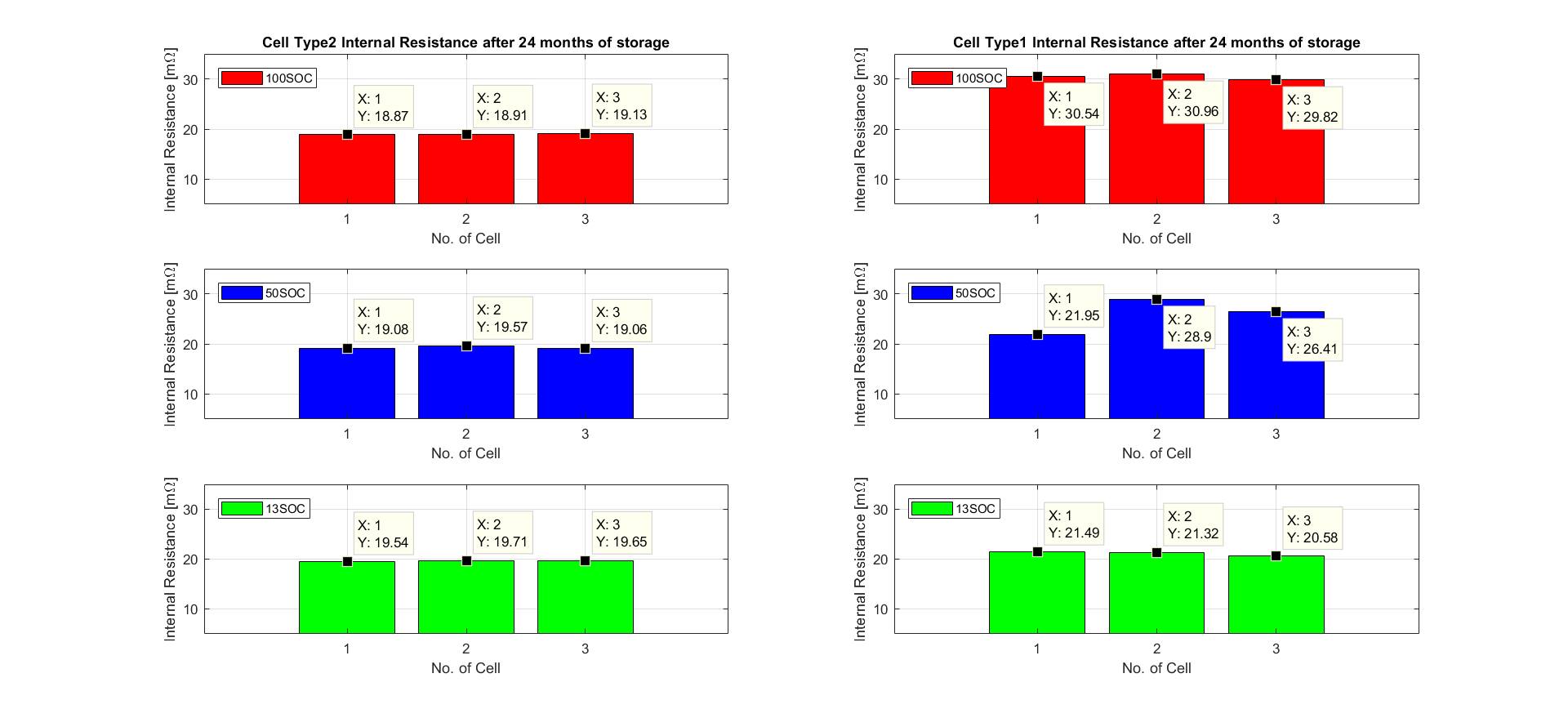

The internal resistance of cells changes along with aging, but this change is not same for all the manufacturers. Figure shows a huge difference in internal resistance for two different manufacturers (same cell chemistry / same cell format).

During the aging test we keep track of both capacity and internal resistance at 3 different SOC (100SOC, 50SOC & 13SOC) to understand the optimal usable range of the cell.

Training

Training session will provide an in-depth understanding of lithium battery production procedures, operation, safety and other technical issues, which will help to become a lithium battery expert.

Training Content

- Different battery technologies

- Different types of lithium battery

- Main components of the battery

- Different cell formats

- Battery manufacturing process

- Operating principle

- Proper understanding of battery Terminology/ keywords

- Practical test session with cell tester

- Battery Internal Safety Mechanism

- Battery degradation and how to improve them

- Battery design

- Battery storage condition (example with practical experience)

- Hazardous situation and handling guideline of Lithium Battery

- Next generation cell technologies

Consulting

Consulting with experts is a necessary part to have good quality products. It would save time, money and prevent you from going in wrong direction.

Consulting Topics

Cell Selection- Existing cell technologies assessment

- Cell selection for a given application

- Support on cell evaluations and validation

- Support on selecting the optimal cell supplier

- Application dependent battery design

- Battery purchasing criteria

- New cell technologies assessment

- Best usable voltage range

- Best usable temperature range

- Methods of reducing faulty cells from suppliers

- Methods of reducing field failure rate